As one of the largest and most experienced plastic molding companies in the world, StockCap employs a number of secondary or finishing operations that allow us to be more of a single source supplier to our customers.

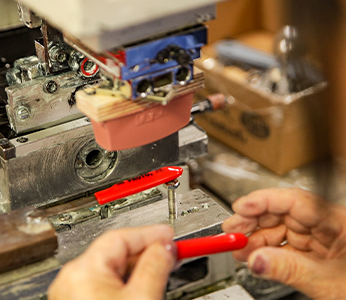

Printing

Our in-house finishing department utilizes multiple processes to apply single or multi-color prints to our molded products.

- Silkscreened

- Pad Printed

- Heat Stamped

- Decal

Print your company name, address, trademark, warnings, or instructions assured our high gloss plastisol inks fuse into vinyl and won't flake or fade.

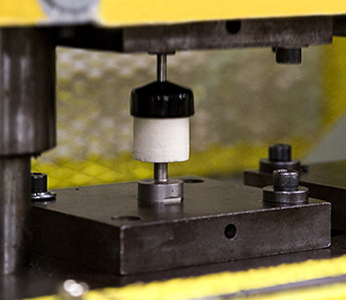

Punching & Slicing

StockCap utilizes high speed equipment to modify molded products to your specific needs. Typical operations include:

- Slicing long caps into sleeves

- Punching holes or slits in top of caps

- Cutting parts as needed

These "secondary operations" allow us to be more of a single source supplier while creating solutions that are typically a much more cost effective alternative to custom molding.

Quality Assurance

While every molded product is manufactured in accordance with ISO standards, StockCap utilizes additional quality processes including:

- Vision Inspection

- Material Analysis

- Secondary Washing

- Custom Testing

These additional quality assurance processes are available to those requiring higher level specifications, testing and certifications.

![]()

Washing

Need parts that are free of mold lubricants or delivered in an extra clean state? When specified, we can utilize our industrial washing process to ensure parts are void of any external substances.

![]()

Custom Packaging

While most of our products are shipped in bulk boxes or bags, we can work with you to develop custom packaging for your specific needs. While minimums typically apply, we can package caps in smaller quantities, special bags or boxes, etc.