StockCap uses a variety of materials in the production of plugs, caps and all our other products. Vinyl may be the most economical, but rubber products can often be reused for longer periods. Plastic caps and plugs are typically firm, not flexible like vinyl. All materials are generally weather resistant. For deeper comparison, review our material properties chart by clicking on the button below or view our regulatory statement by clicking the second button shown here.

Download Material Properties Review Regulatory Statement

Some materials are not compatible with the various applications of our products. For example, our high temperature vinyl products can be a money saving alternative for some paint masking applications, but would not withstand the higher temperatures that silicone products can endure.

- It is the responsibility of the purchaser [of our products] to determine the use of our product(s) as safe, lawful and technically suitable in their intended applications.

- Our vinyl products do not meet the Food and Drug Administration requirement of 21 CFR 177 for contact with food.

- Most of the materials used in the manufacturing of StockCap products can be recycled, however, it is necessary to check with your local recycling center for a list of accepted materials.

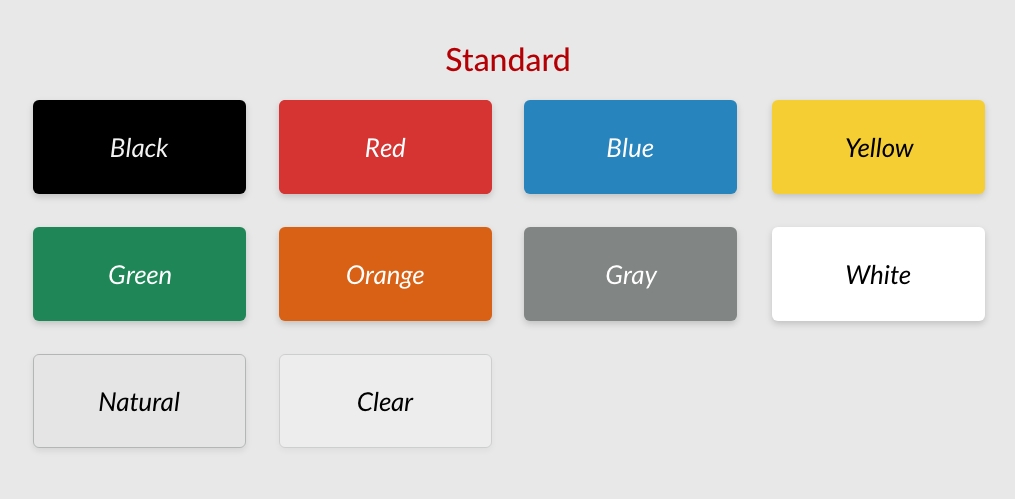

Caps are manufactured in 8 standard colors for multiple materials. Custom colors are also available.

Standard Lead Time

(~ 3 Weeks)

Longer Lead Times and

Higher Minimums

*Custom color-matching

fees may apply.

| Standard Vinyl | High-Temp Vinyl | EPDM | Silicone | |

|---|---|---|---|---|

| Max Temperature | 225° F (107° C) | 446° F (230° C) | 475° F (246° C) | 600° F (316° C) |

| Painting - Air Dry | Lowest cost alternative. | Functions well. Higher cost alternative. | Functions well. Costly alternative. | Functions well. Costly alternative. |

| Painting with Bake up to 350° | Will withstand some low-cure processes. | Works in most processes at significantly less cost than Silicone or EPDM. | Typically only used if Hi-Temp vinyl does not perform. | Functions well. Costly alternative. |

| Powder Coating | Less effective than high-temp vinyl. | Works in some processes especially when using large masks. One time use. Wash caps to remove any mold release. | Works in most processes. Fewer passes than Silicone products. | Works in nearly every process. Get multiple passes as powder is easily cracked off. |

| E-Coating | Typically will not withstand bake temperatures. | Low cost alternative. Specify industrial wash to eliminate mold release. | Works in most processes. Fewer passes than Silicone products. | Works in nearly every process. Get multiple passes as powder is easily cracked off. |

| Plating | Lowest cost alternative, but some chemicals may break them down. | N/A | Great chemical resistance makes these a safe choice for most plating processes. | Costly alternative. |