Unique dip molding process allows hundreds of design possibilities by varying wall thickness, hardness, inside length and surface texture.

Step 1 — Choose an Inside Diameter (A)

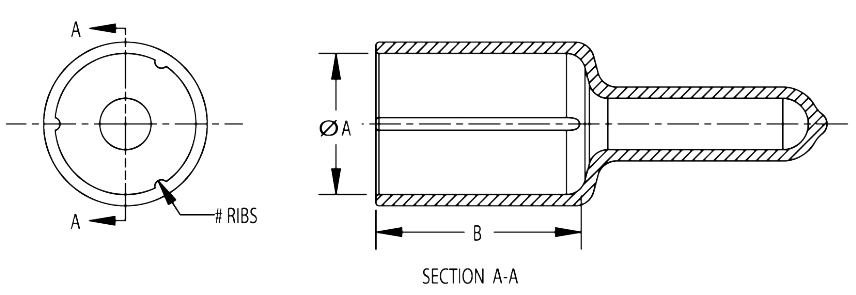

Vented Caps are soft and flexible and an undersized diameter for a tight fit is suggested. For example, if your outside diameter is 0.500″, use a 0.437″ Vented Cap.

- These caps do not depend on any mechanical devices and are easily applied and removed.

- The caps are designed to vent the gases that build up in sealed environments.

- Vented Caps relieve the vacuum created when a hot product cools.

Step 2 — Choose a Length (B)

Production Vented Caps are available in any length, in 0.062″ increments. Minimum length is 0.187″. Maximum length is dependent upon the diameter.

- Inside length tolerance is +/- 0.062″.

- Inside length is measured along the side wall to the radius of the closed end, not down the center.

Wall Thickness “C” is measured 0.250″ from the open end, increasing slightly toward the closed end. Wall tolerance is +/- 0.010″.

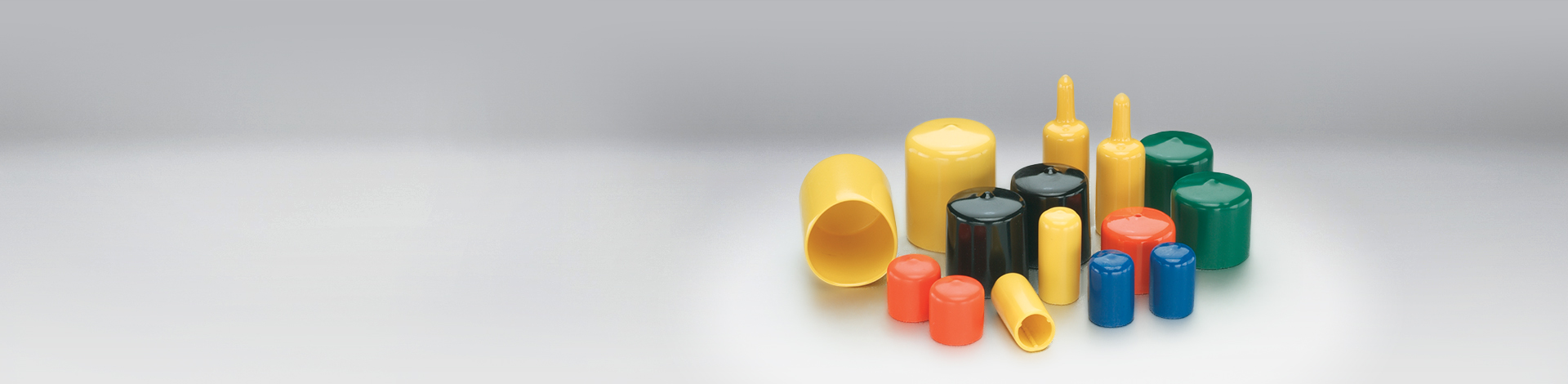

Vented Short Cap

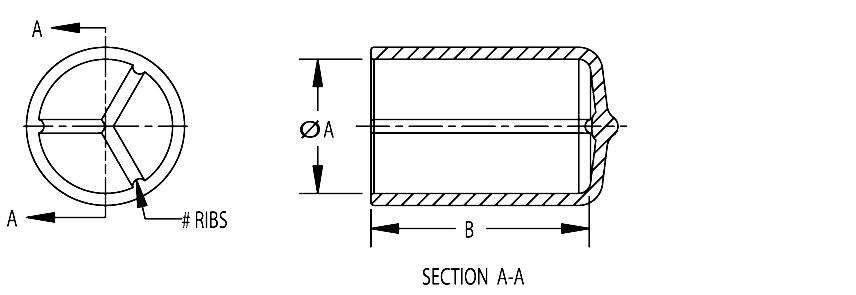

Vented EZ Tab Cap

Vented Grab Tab Cap

These items are not available for online purchase. Please call to discuss options or submit our Quote/Sample form.

Vented Caps

| Inside Diameter “A” | Maximum Length “B” | Number of Ribs | Style |

|---|---|---|---|

| 0.614 | 1.500 | 3 | Short Cap |

| 0.735 | 1.250 | 2 | Grab Tab |

| 0.825 | 1.750 | 3 | EZ Tab |

| 0.937 | 1.750 | 1 | EZ Tab |

| 1.240 | 1.062 | 1 | Short Cap |

| 1.375 | 1.500 | 1 | Short Cap |

| 1.420 | 1.500 | 3 | Short Cap |

| 1.625 | 2.000 | 3 | Short Cap |

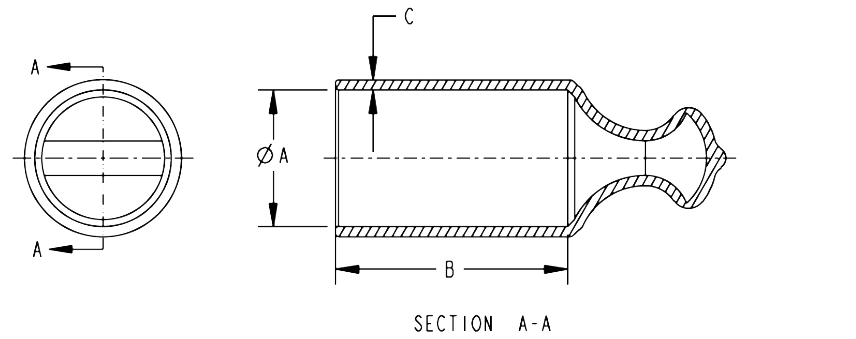

Step 3 — Choose a Color

Caps are manufactured in 8 standard colors for multiple materials. Custom colors are also available.

Standard

Custom

Step 4 — Choose a Material

Vented Caps are made from a 75 durometer PVC with a smooth surface and glossy finish. However, these caps can be made in materials with a variety of characteristics and features as shown below.

Material Characteristics

1. Hardness

2. Gloss

3. Texture

4. Special Features

-

High Temperature Resistant

-

Highly Weather Resistant

-

Fire Resistant (UL Qualifiable)

-

Anti-Static

-

Dilatable

Step 5 — Add Further Customization

At StockCap, our service extends beyond molding protective caps, plugs and covers to include a variety of finishing and packaging options. We have an entire facility set up to print, punch, package and more so that your team can focus on what you do best.