Specifically designed for powder coating and E-coating masking applications, StockCap’s silicone caps will resist temperatures up to 600°F (316°C) and have a service life beyond a single use.

Key Features

Resists up to 600°F

Silicone’s ability to function under extreme heat for extended periods of time has made it the masking product of choice for high temperature painting and powder coating.

No Risk of Contamination

Unlike silicone “lubricants” that can wreak havoc in a coating facility, silicone caps are solid material and pose no contamination risk to a coating line.

Medical Packaging

Used extensively in the medical packaging field as silicone is a very pure material that can easily withstand the sterilization temperatures used in this market.

Materials

50-60 durometer silicone rubber with a tensile strength of 1300 PSI and elongation of 330% that resists temperatures up to 600°F (316°C)

Additional Features

- Withstand multiple passes through most coating processes

- Custom sizes available with minimal tooling investment

- Stretch to provide an air tight seal

- In stock for immediate shipment

Applications

- Painting

- Powder Coating

- e-Coating

Colors

FEO Red with custom colors available upon request.

Silicone Caps

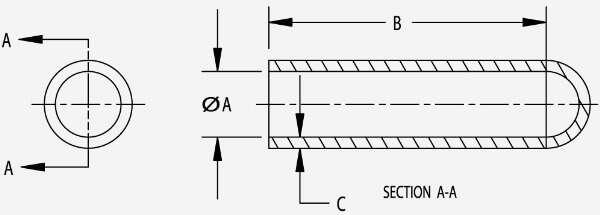

| Inside Diameter “A” | Inside Length “B” | Wall Thickness “C” | |||

|---|---|---|---|---|---|

| Inches | mm | Inches | mm | Inches | mm |

| 0.020 | 0.508 | 0.500 | 12.70 | 0.060 | 1.52 |

| 0.034 | 0.864 | 0.500 | 12.70 | 0.060 | 1.52 |

| 0.046 | 1.17 | 0.750 | 19.05 | 0.060 | 1.52 |

| 0.062 | 1.57 | 0.750 | 19.05 | 0.060 | 1.52 |

| 0.070 | 1.78 | 1.000 | 25.40 | 0.060 | 1.52 |

| 0.093 | 2.36 | 0.750 | 19.05 | 0.060 | 1.52 |

| 0.100 | 2.54 | 0.500 | 12.70 | 0.060 | 1.52 |

| 0.109 | 2.77 | 0.750 | 19.05 | 0.060 | 1.52 |

| 0.125 | 3.18 | 0.500 | 12.70 | 0.060 | 1.52 |

| 0.125 | 3.18 | 1.000 | 25.40 | 0.060 | 1.52 |

| 0.140 | 3.56 | 0.500 | 12.70 | 0.060 | 1.52 |

| 0.140 | 3.56 | 1.000 | 25.40 | 0.053 | 1.35 |

| 0.148 | 3.76 | 1.000 | 25.40 | 0.060 | 1.52 |

| 0.156 | 3.96 | 0.500 | 12.70 | 0.060 | 1.52 |

| 0.156 | 3.96 | 1.000 | 25.40 | 0.060 | 1.52 |

| 0.172 | 4.37 | 0.500 | 12.70 | 0.060 | 1.52 |

| 0.172 | 4.37 | 1.000 | 25.40 | 0.060 | 1.52 |

| 0.187 | 4.75 | 0.500 | 12.70 | 0.060 | 1.52 |

| 0.187 | 4.75 | 1.000 | 25.40 | 0.060 | 1.52 |

| 0.218 | 5.54 | 1.000 | 25.40 | 0.060 | 1.52 |

| 0.223 | 5.66 | 1.000 | 25.40 | 0.060 | 1.52 |

| 0.234 | 5.94 | 1.000 | 25.40 | 0.060 | 1.52 |

| 0.234 | 5.94 | 1.500 | 38.10 | 0.060 | 1.52 |

| 0.250 | 6.35 | 1.000 | 25.40 | 0.060 | 1.52 |

| 0.281 | 7.14 | 1.000 | 25.40 | 0.060 | 1.52 |

| 0.295 | 7.49 | 1.000 | 25.40 | 0.060 | 1.52 |

| 0.295 | 7.49 | 1.500 | 38.10 | 0.060 | 1.52 |

| 0.313 | 7.95 | 1.000 | 25.40 | 0.060 | 1.52 |

| 0.340 | 8.64 | 1.000 | 25.40 | 0.060 | 1.52 |

| 0.355 | 9.02 | 1.500 | 38.10 | 0.060 | 1.52 |

| 0.375 | 9.53 | 1.000 | 25.40 | 0.060 | 1.52 |

| 0.375 | 9.53 | 1.500 | 38.10 | 0.051 | 1.30 |

| 0.406 | 10.31 | 1.000 | 25.40 | 0.060 | 1.52 |

| 0.437 | 11.10 | 1.000 | 25.40 | 0.060 | 1.52 |

| 0.456 | 11.58 | 1.500 | 38.10 | 0.060 | 1.52 |

| 0.468 | 11.89 | 1.000 | 25.40 | 0.060 | 1.52 |

| 0.480 | 12.19 | 1.500 | 38.10 | 0.060 | 1.52 |

| 0.500 | 12.70 | 1.500 | 38.10 | 0.060 | 1.52 |

| 0.535 | 13.59 | 1.500 | 38.10 | 0.060 | 1.52 |

| 0.562 | 14.27 | 1.500 | 38.10 | 0.060 | 1.52 |

| 0.600 | 15.24 | 1.500 | 38.10 | 0.060 | 1.52 |

| 0.625 | 15.88 | 1.500 | 38.10 | 0.060 | 1.52 |

| 0.687 | 17.45 | 1.500 | 38.10 | 0.060 | 1.52 |

| 0.730 | 18.54 | 1.500 | 38.10 | 0.070 | 1.78 |

| 0.750 | 19.05 | 1.500 | 38.10 | 0.060 | 1.52 |

| 0.812 | 20.62 | 1.500 | 38.10 | 0.060 | 1.52 |

| 0.875 | 22.23 | 1.500 | 38.10 | 0.060 | 1.52 |

| 0.937 | 23.80 | 1.500 | 38.10 | 0.060 | 1.52 |

| 0.970 | 24.64 | 1.500 | 38.10 | 0.072 | 1.833 |

| 1.000 | 25.40 | 1.500 | 38.10 | 0.060 | 1.52 |

| 1.062 | 26.97 | 1.500 | 38.10 | 0.060 | 1.52 |

| 1.125 | 28.58 | 1.500 | 38.10 | 0.060 | 1.52 |

| 1.187 | 30.15 | 1.500 | 38.10 | 0.060 | 1.52 |

| 1.250 | 31.75 | 1.500 | 38.10 | 0.060 | 1.52 |

| 1.500 | 38.10 | 1.500 | 38.10 | 0.060 | 1.52 |

| 1.750 | 44.45 | 2.000 | 50.80 | 0.060 | 1.52 |

| 1.875 | 47.63 | 2.000 | 50.80 | 0.060 | 1.52 |

| 2.000 | 50.80 | 2.000 | 50.80 | 0.060 | 1.52 |