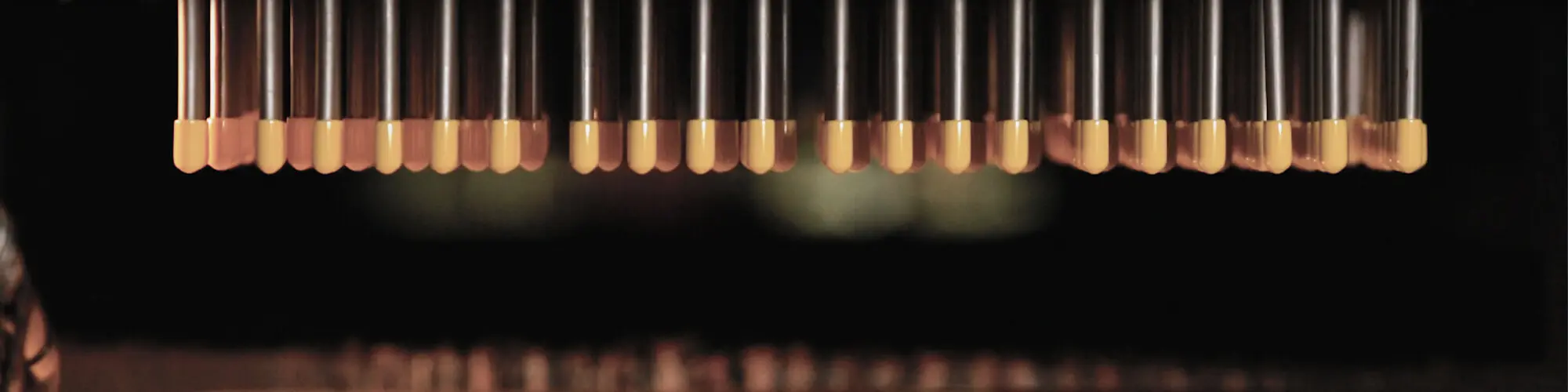

As one of the largest and most experienced vinyl dip molders (VDM) in the world, StockCap’s worldwide VDM operations service its customers with all types of vinyl caps, plugs, covers and closures.

Why Consider Dip Molding?

Dip molding has unique characteristics that enable StockCap to produce a wide variety of unique solutions with the following attributes.

- Low tooling costs…typically a fraction of injection molding

- Quick and inexpensive prototypes

- Short lead-times on custom tooling…weeks versus months

- No internal stress molded into parts

Key Features

More Material Options

The breadth of our business and our extensive material compounding capabilities allow us to offer the largest selection of materials in the industry at extremely competitive prices. By mixing our own plastisol we avoid the mark-up that most molders pay to compounders and we are able to recycle most of our plastisol – reducing our environmental footprint and eliminating expensive disposal costs.

Over the years, we have developed over 500 formulas for the varying needs of our customers.

In House Engineering and Prototypes

Our in-house engineering specialists around the world utilize their expertise in closure design to explore all possibilities in determining the best design and material for your packaging application. Our goal is to design your part in the most cost effective manner and to design it to deliver the highest level of performance required.

Design

Not only do we have over 70 years of design experience, but we utilize some of the most sophisticated design and manufacturing software. We pioneered the use of AutoCAD and Pro-Engineer software in our industry and are able to collaborate with all our locations – using PTC Creo and Siemens NX programs – to seamlessly integrate the tooling fabrication process.

Prototyping

One of the primary benefits of dip molding is related to its inexpensive and accurate prototyping process. With a dedicated sample lab producing parts daily, we are able to provide prototypes for engineering and marketing tests at an insignificant cost.

The Process

The dip molding process is unique in its ability to manufacture caps and closures in extremely high volumes utilizing innovative machine designs that allow us to make many different sizes, shapes and styles of caps on closures.