StockCap’s Product Protection Specialists work with our sister companies VisiPak and GripWorks to develop a variety of extruded vinyl, plastic and foam solutions.

Extruded Vinyl Tubes

Extruded, soft plastic, vinyl tubing offers a cost effective option for those looking to add some protection or covering to a bar or handle.

Vinyl tubing is available in both glossy and flat finishes in many different colors. It can be extruded and cut in-line to the length specified – making it ideal for high volume applications that demand low cost solutions.

While extruded tubing is very cost effective, its cushioning properties and surface textures are relatively limited. For this reason, many people will opt to use vinyl dip molded long caps or grips – sliced to create an open-ended sleeve.

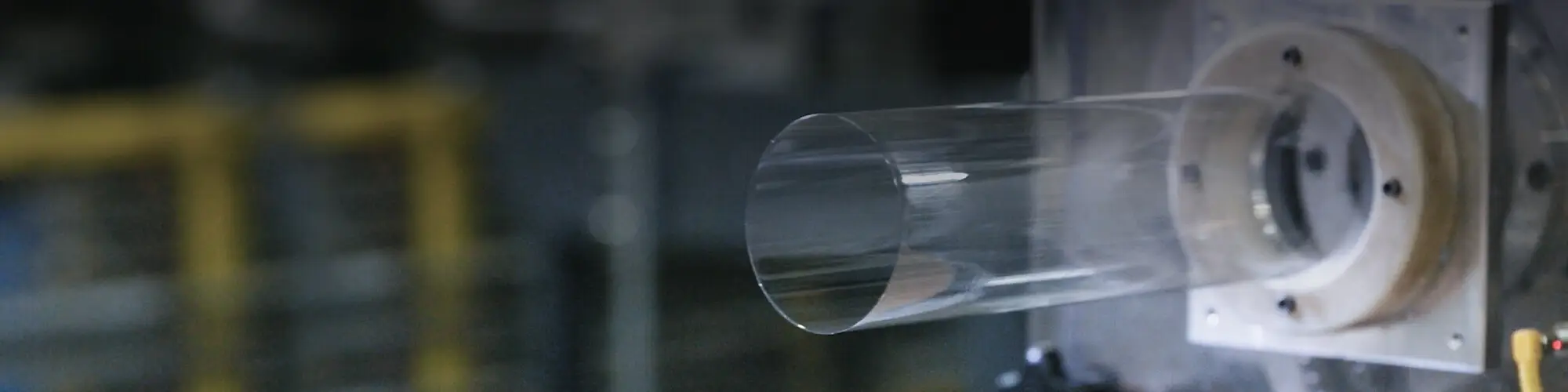

Extruded Plastic Tubes

Our sister company, VisiPak, specializes in the extrusion of clear plastic tubes. The most common use of these tubes is for retail and industrial packaging application which align nicely with StockCap’s focus on Product Protection.

This image shows an example of a clear plastic tube that was designed to not only protect consumers from the sharp point on the screw, but also protect the threads and serve as a handle for installing the screw into the ground.

Benefits of Extrusion

Extrusion is typically a very economical manufacturing option due to its efficiency and small amount of material waste. This process is used for all types of tubing as well as seals and fiber optic cable.

Most Economical Choice

Highly Efficient Process

Minimal Wasted Material

Extruded Foam Tubes

Our sister company, GripWorks, manufactures a complete line of extruded foam tubing which represents the pinnacle of product protection. These foam tubes and pads are often used on items like bike racks to protect the vehicle from coming into direct contact with the metal tubing of the rack.